| ConsoliTech Corp. Industrial Control Systems |

Visual Basic

OPC HMI Industrial Control Toolkit VB/Control Toolkit Features |

|---|

| Home Page | VB/Control Specs | Product List and Pricing | Demos | Notebook Computer Enclosure | PLC Communications OCX's |

| VB/OPC

Control is our

Windows / Visual Basic solution for your HMI / SCADA industrial

control needs. This toolkit package is an integrated collection of OPC ActiveX client controls and OPC servers , templates and functions designed to rapidly get your application up and

running. By combining our tools with Microsoft's powerful Windows based Visual Basic

or VB.Net , you

can quickly transform your concept into a full working User Interface solution. All this

at a fraction of the cost of other proprietary control interface programs. Visual Basic OPC industrial control development toolkit ActiveX controls and servers link your application to the factory floor PLC. VB/ OPC Controls are Visual Basic toolbox objects that can be dragged onto your projects form. Properties are set by filling in the controls properties window. Controls automatically link to the I/O server/driver which scans the PLC data. Your project can be setup with No or minimal coding!! - No hardware keys required!! |

Toolkit templates I/O OPC Controls - States, buttons, Textbox, Slider, Bargraph, Gauge, OptionButton, CheckBox - I/O OPC ActiveX control tools for States(input value sets control state-text,color,picture,etc.; Output Push Buttons; Read/write Textbox- display PLC value, edit and write to PLC; Output Slider-send scaled value to PLC; Input Bargraph; Input Gauge; Output OptionButton-write selected option; Output CheckBox - write ON or OFF Alarming - Active and historical alarms. Fill out form with Tag Name, I/O trigger values, user message. If a point triggers an alarm, a message will be displayed in listbox window. Active alarms are current. Historical are all current and previous alarms. Data Logging - Log I/O data to hard drive and view in time selectable window. Stored in MS Access database. Can be exported to Excel. Trending - real time graphs (200-800 throughput/sec) of I/O data Part setup (recipe) - Link MS Access database forms and send editable data to PLC. SPC - Statistical Process Control , X-Bar & Range Maintenance Log - Access database |

| OPC PLC communications with I/O scanning and modem support - Communicate with PLC's and Data acquisition hardware. OPC PLC servers or ActiveX drivers for:

|

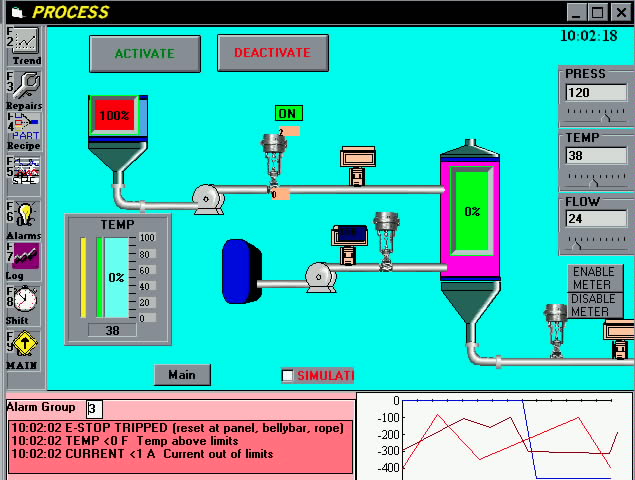

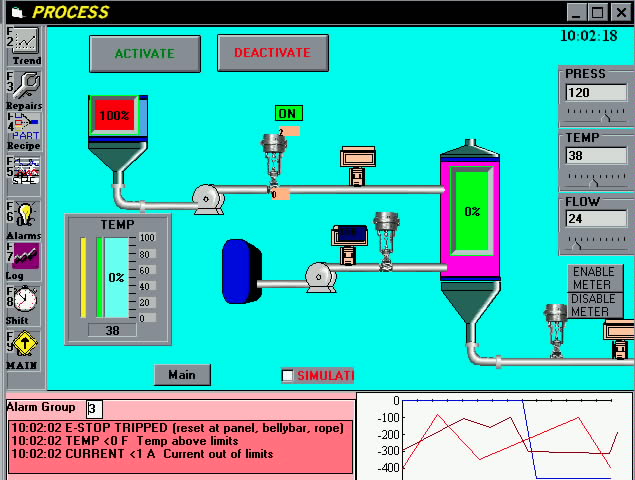

Example of a process graphic with real time links with PLC data. Windows displaying

current process alarms and graph of current data. By setting alarms group, only alarms

within user set group are displayed.

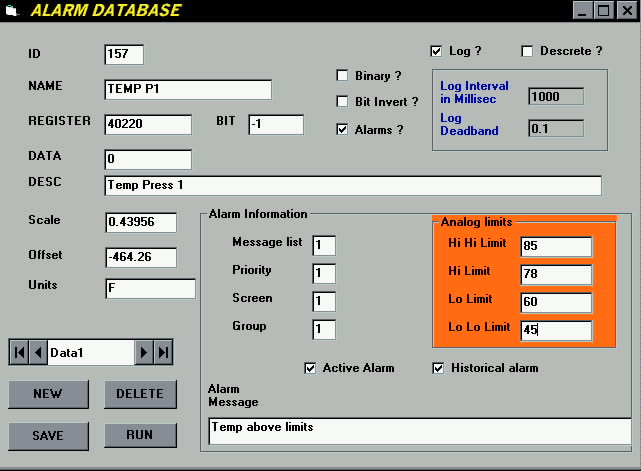

| Tag Name /Alarm /

Log database setup Interactively setup alarms using our Alarms Builder program. Simple fill in the database form for each alarm point. Either a discrete bit, register bit, register binary value or analog limit may be used. PLC data may also be scaled and logged to disk |

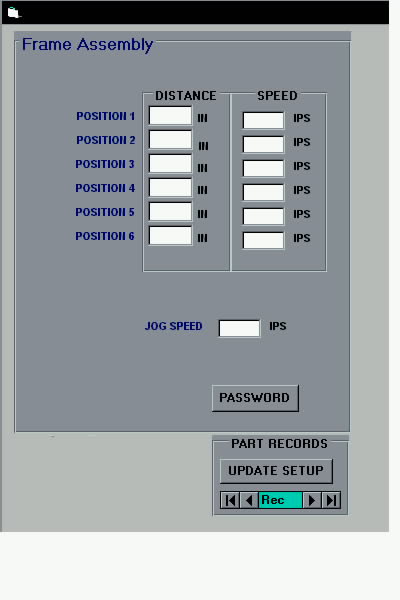

| Part Setup (recipe) Build elaborate part setup forms using our templates. Link form fields to Access database with part number as record. Operator can select part number from drop-down combo box. Password protect data edit for authorized personnel only. |

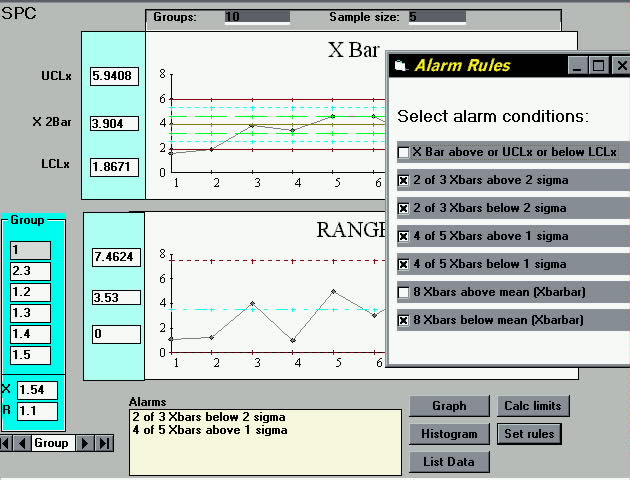

| SPC Use our SPC template to set up simple X Bar and R charts. Move PLC data into SPC database in standard groupings and let our program do the number crunching. Set alarm rules for various out of limits conditions simply by selecting option boxes. Data will be checked against rules during plot and annunciated if out of bounds. |

| Creating Control Programs Simply load in our forms ActiveX / templates, modify them or build your own all in Visual Basic. Use our PLC servers / drivers to link data with your program by filling in our scan data form with PLC locations, setup our Tagname database form. Then use the I/O control tool to link your application to real world I/O. All with no or minimal coding. |

Visual Basic has become the de facto Windows Basic language

standard. Microsoft has standardized on VB as the macro language replacement for all their

core software products such as Access database and Excel spreadsheet. Unlike other HMI

(MMI) packages which force you to learn their limited proprietary script language, anyone

familiar with programming an Excel spreadsheet can also program VB/Control.

Copyright © 1996-2005 ConsoliTech Corp. All rights

reserved.

Information in this document is subject to change without notice.

Other products and companies referred to herein are trademarks or registered trademarks of

their respective companies or mark holders.